Quality Control

Quality Control

Quality Control

Our company uses various methods such as engineering and quality inspection through quality control to maintain and maintain product quality. We provide a ervice that aims to improve. In a broader sense, through a series of systematic measures to produce the most marketable products in the most economical way, we help customers solve potential difficulties and reduce costs by reducing defects.

It is most important to improve productivity and produce high-quality products through quality management and management, and integrate all substructures such as quality, production, and materials into one, quality planning and design, statistical processing of data necessary for quality management, and quality cost We manage all tasks related to management, standardization and quality management, and actively cooperate with standardization of product standards, quality planning (QP), quality control (QC), quality assurance (QA), quality improvement (QI) and productivity improvement.

Agency inspection

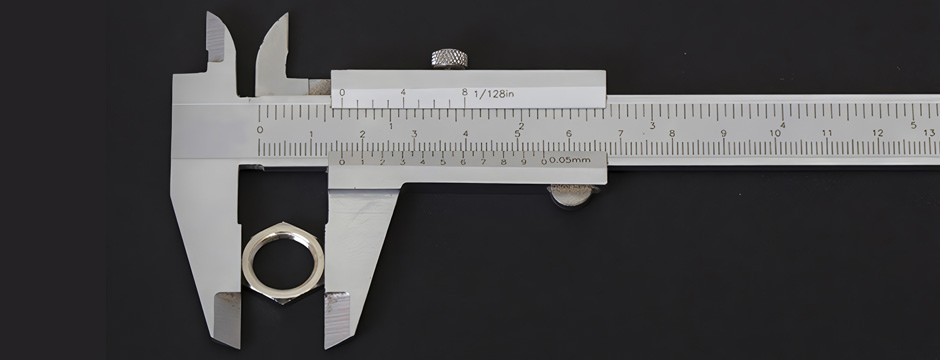

Experience an effective on-the-spot inspection of your products. The witness inspection through the existing inspection agency is document-oriented rather than actual product verification. If the verification of the actual product is not done properly, the documents have no meaning. SE TECH & SERVICE has various verification capabilities related to product manufacturing, such as the ability to read various manufacturing specifications related to products, dimensional inspection, and assembly, starting with the quality system ISO9001.

Customers can save time and money through the inspection agency of SE TECH & SERVICE inspection experts, and can be provided with a professional verification system. SE TECH & SERVICE has professional manpower with more than 10 years of experience in product inspection, and conducts on-the-spot inspections focusing on actual products, out of the existing document-oriented.

SE TECH & SERVICE's inspectors have all-round inspection capabilities, not only product inspection, but also specification reading, compliance, and document eview. From appearance inspection to document review, professional on-site inspectors provide inspection agency services.

Inspection work

- 01

Acceptance inspection of materials

- 02

Acceptance inspection of outsourced processed products

- 03

Inspection of semi-finished and finished products

- 04

Inspection, maintenance, and storage of inspection instruments

- 05

Recording of inspection reports, reporting and storage of data and preparation

- 06

External test request and examination

Conduct of

inspection

1. When an inspector receives an inspection request according to the matters of the inspection request company or requires an inspection during the anufacturing process, the inspector conducts inspection in accordance with the relevant inspection standard.

2. Due to the nature of our company, it is possible to omit some of the characteristic tests in the supplier's own report.

SE TECH & SEVERVICE

provides the following

services.

Quality Consulting

- 1.

Transfer of the quality level and other companies’ best practices suggested by the global quality management model

- 2.

Standard process establishment and development methodology tailoring guide

- 3.

Quality indicator definition and goal establishment guide for quantitative quality management

- 4.

Quality control and testing tool application guide and setup support

Quality Engineering

- 1.

Product design

- 2.

Process design and improvement

- 3.

Real-time process management

Quality Inspection

Visual Inspection, Assembly Inspection, Marking Inspection, Dimensional Inspection, Drawing Inspection, Welding Inspection, Plating Inspection, Test Report